Fitness for Service (FFS) Assessment

FFS or Fitness for Service assessment is an approach is being used in the oil and gas industry in order to assess safe continued operation of assets at presence of defects such as Corrosion (local and general metal loss), dents, gouges, etc. The assessment requires analysing the past and recent inspection data, usually in forms of NDT or In-Line Inspections (ILI) data, listed all the anomalies detected as a result of the inspections.

As part of ay FFS assessment, Z-Subsea integrity experts perform the following activities:

- Review and analysis of the recently gathered NDT and ILI reports and matching/comparing that with the historical data gathered for the similar asset in order to establish the growth rate variation over the time (Box or signal to signal matching)

- Highlighting the most critical features that need immediate integrity assessment

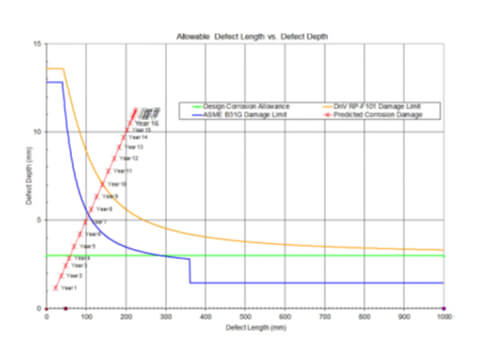

- Calculation of safe working pressure for the asset at presence of those critical features according to DNV RP-F101, API579-1/ASME FFS-1, RSTRENG, PDAM, etc.

- Calculation of Remaining life of the asset at presence of the critical features, grown at a rate which is usually calculated by Z-Subsea flow assurance/process engineers or during the box or signal matching exercise

- Calculation of the inspection intervals

- Development and implementation of the repair procedures and philosophies

Engineering Criticality Assessment (ECA)

ECA or Engineering Criticality Assessment is a Fracture mechanics based approach in that significance of cracks and crack-like features either in the weld (Lack of Fusion, Lack of Penetration, Slag inclusion, etc.) or in the parent metal (Lamination, Lamellar tearing) on the integrity of an oil and gas component is assessed. This approach is proved to be very cost-effective as it avoids unnecessary repairs.

Z-Subsea integrity team has been actively involved in the development of the ECA related codes/standards such as BS7910, DNV OS-F101 (Appendix A), SINTAP and FITNET and use of codes such as DNV RP-F108, API579-1/ASME FFS-1. That said we are confident that we are aware of the cutting edge developments on the relevant/international standards which could be easily pass on to our client in their projects.

At Z-Subsea, we have in-depth knowledge of using the ECA approach during the projects full life cycle (from the conceptual phase, Fabrication, Construction, Operations up to the end of asset life) and beyond (Life extension) under both static (Fracture) and cyclic loading (Fatigue). Engineering Criticality Assessment (ECA) of installations and operations in extreme conditions, i.e., strain-based installations (Reeling or installations in the deepwater), High Temperature and High Pressure (HP&HT) operations and exposure to the hostile environments such as sour-service (high level of H2S), are also amongst Z-Subsea cutting edge expertise and in-depth knowledge on the subject.

The outcome of the ECAs would be in forms of tolerable defect sizes (acceptable flaw depth versus defect length) for a project full life cycle, indication of fatigue life of a welded/non-welded component and determination of the inspection intervals.