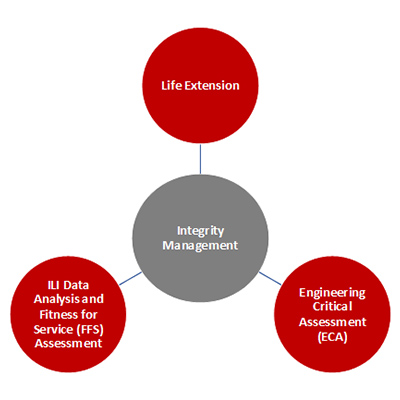

Asset Integrity Management

At Z-Subsea, a risk based approach is used to manage integrity of the new and existing assets from the design stage until abandonment. Our full life cycle integrity management system covers:

- Integrity at design

- Integrity at comissioning

- Integrity at life extension

- Integrity at de-commissioning

The steps involve in such management tasks include:

- Itemizing large assets into smaller sub assets and components

- Identifying threats and their associated failure mechanisms for each component based on concepts of FMEA or FMECA

- Calculation of probability and consequences of failure followed by risk (Qualitative or Quantitative)

- Construction of a project-specific Risk matrix incorporating client’s corporate risk matrix

- Highlighting high risk areas that require alteration, operational change and/or more frequent inspections

- Running Risk Assessment workshop inviting client’s technical representatives to finalize a project specific Risk matrix

- Determination of inspection intervals including In-Line Inspections (ILI) for subsea pipelines

- Issuing project-specific integrity management reports

- Development and implementation of Inspection, maintenance and repair (IMR) philosophies.

- Management of change

- Developing, Implementing and/or auditing of Pipeline integrity management systems (PIMS) or Subsea Integrity Management Systems (SIMS)

At Z-Subsea we see the added value of engaging with our clients on the integrity management from the concept selection stage as to our experience our clients will benefit economically and technically from the results of the integrity management studies at the concept select phase and further during the design and operation.