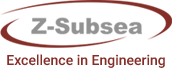

Subsea Pipelines Design

Z-Subsea provide most competent team of experts to deliver a robust and economically viable design to meet the project requirements.The pipeline and riser design process can be based on PD8010, DNV, ASME and other industry recognised standards.

Z-Subsea provide most competent team of experts to deliver a robust and economically viable design to meet the project requirements.The pipeline and riser design process can be based on PD8010, DNV, ASME and other industry recognised standards.

The initial calculations of subsea pipelines wall thickness at FEED stage is based on:

- The hoop stress in the pipe due to differential pressure

- Pipeline collapse due to external pressure

- Buckle propagation due to initiation of a buckle

However, for High Pressure-High Temperature (HPHT) pipelines, consideration should be given to:

- High compressive axial force which could result in near yield stresses. Means of reducing axial stress should be sought at early stages

- Start-up/shut-down cycles for HPHT pipelines will result in considerable fatigue in the girth welds which requires awareness at early stage of the project.

Depending on the linepipe dimensions, a thin or thick wall theory should be used to assess the stresses in the pipe.

There are also other factors in selecting wall thickness for a pipe. For HPHT systems, there are usually HIPPS systems used to protect pipeline from over pressure.

Depending on the HIPPS valve closure time, the pipeline will have a fortified zone. Also, if the protection system upstream, and isolation systems downstream the pipeline fail to react on demand, there is possibility of pipeline over pressurisation which requires probabilistic design against burst or “loss of pressure containment”. Other factors like accidental loads and seismic activities could affect the initial sizing of a pipeline. These accidental or exceptional load cases should be looked at using reliability and probability of failure analysis.